OEM/ODM 3 Cell Cable Flexible Woven Fabric Innerduct manufacturers for Wholesale - High-Quality Fiber Optic Solutions for Global Distributors

- Model

- 3 Cell

Item specifics

- Size

- 50mm

- Material

- Woven Fabric

- Item

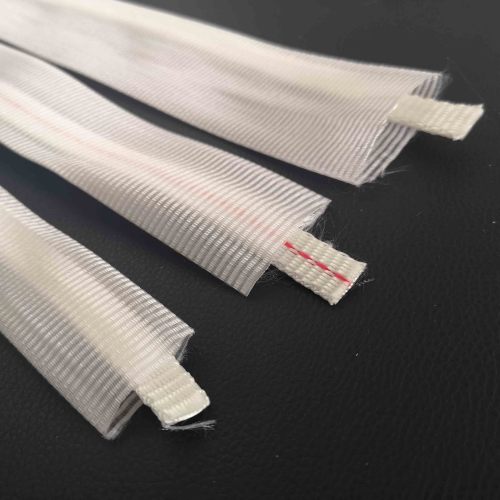

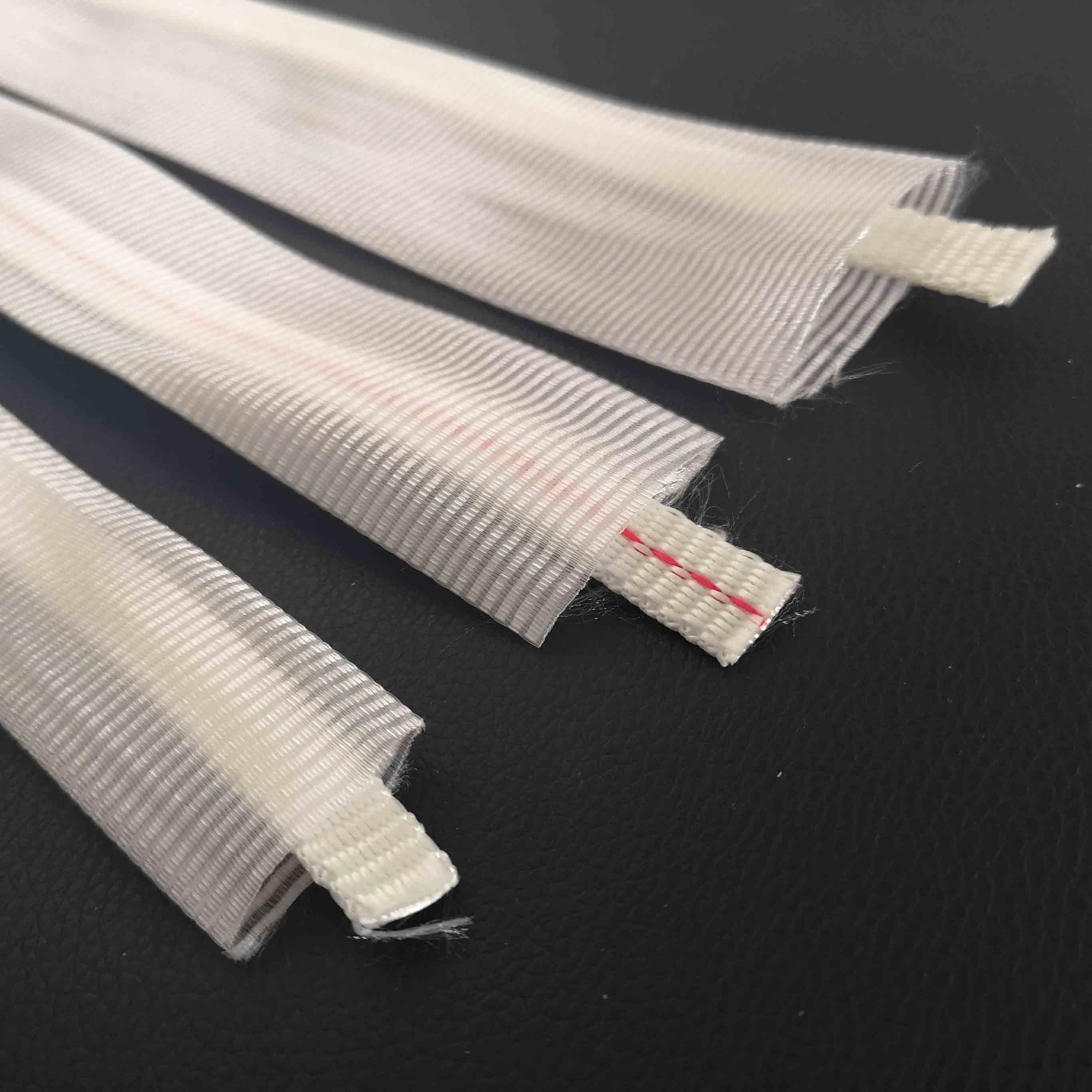

- 3 Cell Cable Woven Fabric Innerduct

Review

Description

Part 1 | |

Product Name | Fabric Innerduct |

Material | Nylon /Polyester |

Color | Nature White |

Weight (g/m2) | 180~200 |

Performance | 1) Unique fabric construction ,flexible shape , save space compare with rigid inner duct. 2) At competitive prices, cut down the investment cost. 3) Easy to install and of speed. |

Part 2 | |

Product Name | Cable Innerduct Color Pull Tape |

Material | High strength Nylon filament |

Width | 11 mm |

Length | 2000m/roll |

Breaking Tensile Strength | 600KG/M |

Performance | Wear-resistant / High strength/ Smooth and easy to pull |

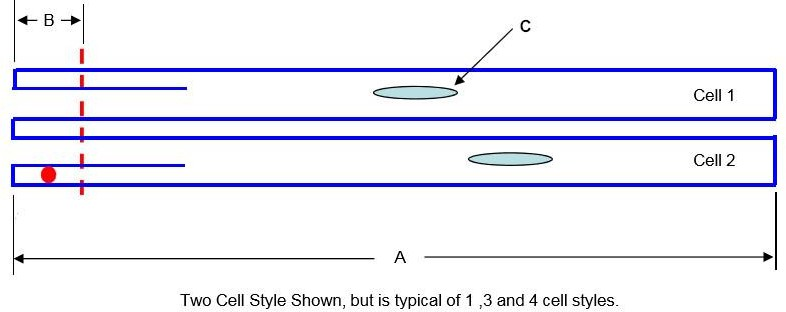

4G / 5G Design Parameters

FABRIC INNERDUCT PRODUCT OFFERING

Style | Maximum Cable Dia,MM | Target Cell Circum | Target Cell Diameter | Width A | Seam B | Pull Tape Width C |

4095-X | 42 | 183 | 57 | 95 | 5 | 11 |

3886-X | 38 | 163 | 52 | 86 | 5 | 11 |

2865-X | 28 | 121 | 38 | 65 | 5 | 11 |

2460-X | 24 | 111 | 35 | 60 | 5 | 11 |

2255-X | 22 | 101 | 32 | 55 | 5 | 11 |

2050-X | 20 | 91 | 29 | 50 | 5 | 11 |

1845-X | 18 | 81 | 26 | 45 | 5 | 11 |

1640-X | 16 | 73 | 23 | 40 | 5 | 11 |

1436-X | 14 | 65 | 21 | 36 | 5 | 11 |

1232-X | 12 | 56 | 18 | 32 | 5 | 11 |

1028-X | 10 | 49 | 15 | 28 | 5 | 11 |

Note : All specifications are subject to change without prior notice.

More Features

1) Light Construction

The textile sub-tube has no bending memory; it does not curl like a PE sub-tube;

The textile sub-tube will not be kinked during laying and can be bent freely during laying;

The textile sub-tube is preset with high-strength draw tape in each hole, and the laying of the cable does not need to be through-hole, and the laying is more convenient and quick;

The construction site requirements are very small, especially suitable for busy districts.

2) Protection Cable And Outer Tube

The breaking strength is above 1000 kg;

Textile tube melting point = 215 ° C, while HDPE sub-tube = 110 ° C;

The thermal expansion and contraction rate of the textile tube is 1/7 of that of the HDPE sub-tube;Prevents wear between cables.

3) Long Lasting

The textile sub-tube has high chemical inertness and can be exposed to a harsh underground environment for a long time. The design life is 30-50 years, and the life of the PE sub-tube is only 15 years.

4) Resolution Recognition Design

Two holes in the textile sub-tube product family, three holes will be preset with different colors of the draw tape for the differentiation during construction;

The textile sub-tube will print the meter mark when it leaves the factory to prevent unnecessary waste during construction;

When the textile sub-tube is delivered from the factory, it will be labeled according to the customer's needs, such as A, B, C A1, A2, A3, etc., used to distinguish the multiple textile sub-tubes in the pipeline, to facilitate the maintenance of the line.

5) Environmentally Friendly Design Concept

The textile sub-tube can reach 30-50 years underground. Ordinary HDPE sub-tubes will form slag due to aging in the ground for a long time, and become a blockage in the pipeline. The textile sub-tube solves this problem from the design concept and has high environmental protection for the pipeline.

We are Woven Fabric Innerduct manufacturers,contact us~