3 questions for fabric innerduct

- Share

- publisher

- Lucy

- Issue Time

- Sep 13,2022

Summary

The following questions for flexible fabric innerduct system specialist were fielded and answered as follows by the company's technical support boss.

Can you field splice Fabric innerduct?

Can you attach the inner fabric channel to the field? The short answer is no. Damage to the fabric inner tube can be repaired in the field but there is no easy repair method to join in place. If youve ever used repair kits in a live environment you know how difficult it is to line up seams. A plastic repair kit joins two pieces in one seam but not two pieces of fabric continuously so it cannot be used as a joint in a pull situation. Inner fabric channels are factory stitched approximately every 600-650 yards. The seam is a lock-stitched construction that spans the entire length of two adjacent sections as one continuous section of the file.

The next question is can you sew the joints in place? Done but you will need an electric sewing machine and someone who knows what they are doing.

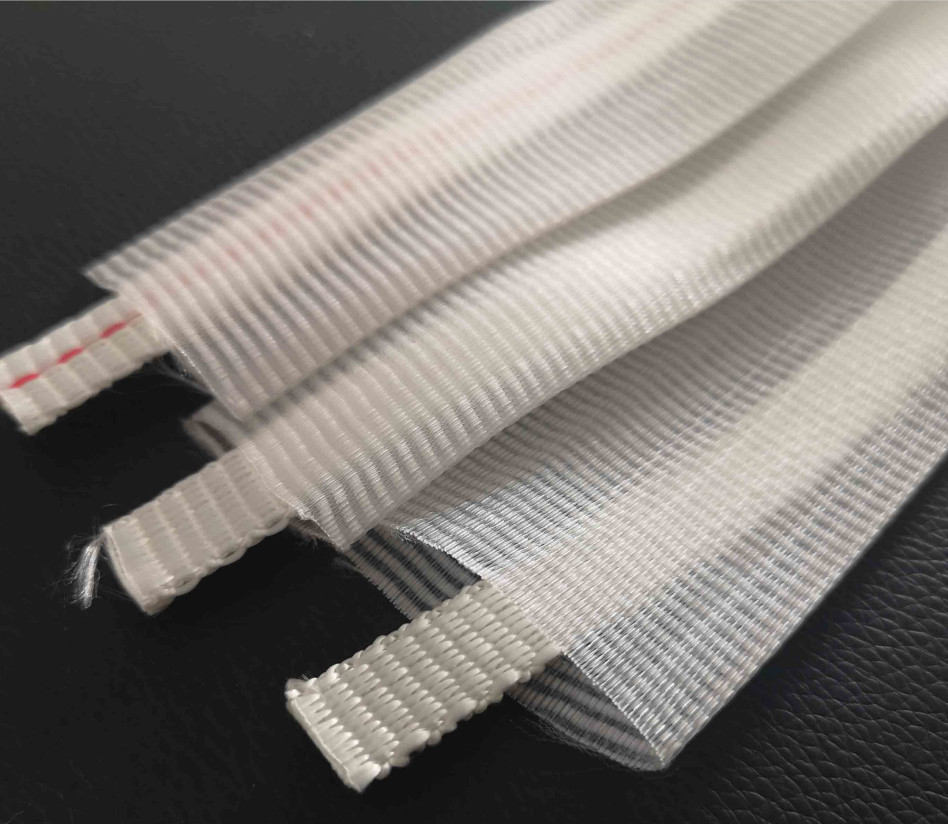

Can you put multiple wires in one cell?

A customer asked the other day if they could put more cables in the cell. I gave them a short answer of yes but its generally not recommended if you want to add or remove cables individually in the future. Each cell has a special way to protect the cable from contact with other cables and if necessary the cable can be removed and replaced with another cable. ISP projects usually have bundled cables because they are short CAT 5/6 type cables usually wrapped in a j cable tray or hook. The group must conduct a cable to calculate the fill ratio if the customer wants to place the ball from the pile. Take the photo on the left for your reference. Single rope and large rudder ropes are about the same size when tied together. If you draw a circle around the file you will have a better idea of the total volume removed from the file.

Will Sunshines inner tube survive the nuclear waste?

The reality is that it is impossible to test a product in every possible situation. The main components of the fabric inner channel are polyester and nylon which are used in various geotextile applications due to their resistant properties. This compound provides excellent corrosion and temperature resistance when exposed to the most common reagents found in underground applications. It includes jet fuel oil diesel natural gas etc. In addition some non-ordinary soil agents have been tested with positive results including hydrogen peroxide transport detergent etc. Our principle is to give an average lifetime exposure to any reagent or ingredient which is difficult to predict as there are many variables such as temperature exposure rate etc but the products are designed to be harsh in most environments.